Lean manufacturing

Lean manufacturing

informationize

informationize

Automation

Automation

Intelligent

Intelligent

In the future, Aibote will continue to innovate, make progress while maintaining stability, promote the implementation of intelligent manufacturing projects, promote the intellectualization of production processes, comprehensively improve the level of informatization, automation and intelligence in the research, development, production, management and customer service of drinking equipment, and the intelligent manufacturing of drinking equipment.

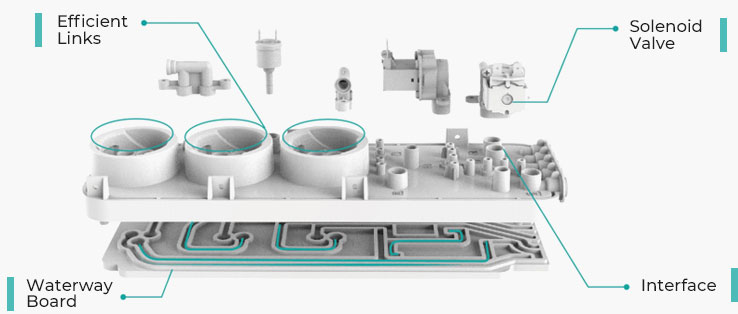

INTEGRATION

Patented technology, simplifying complexity

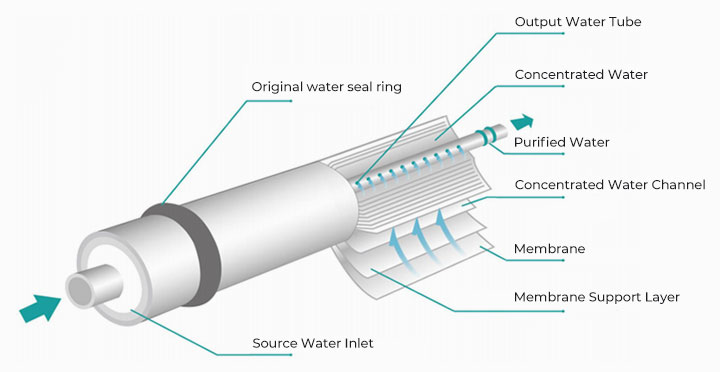

Reverse osmosis filter element

Reverse osmosis technology, referred to as RO, is a very advanced and energy-saving membrane separation technology.

The principle is that under the action of higher than the osmotic pressure of the solution, other substances can not pass through the semi permeable membrane to separate these substances from water. Because the pore diameter of reverse osmosis membrane is very , only one thousandth of a micron, it can effectively remove dissolved salts, colloids, microorganisms, bacteria, organics, heavy metals and other harmful substances in water.

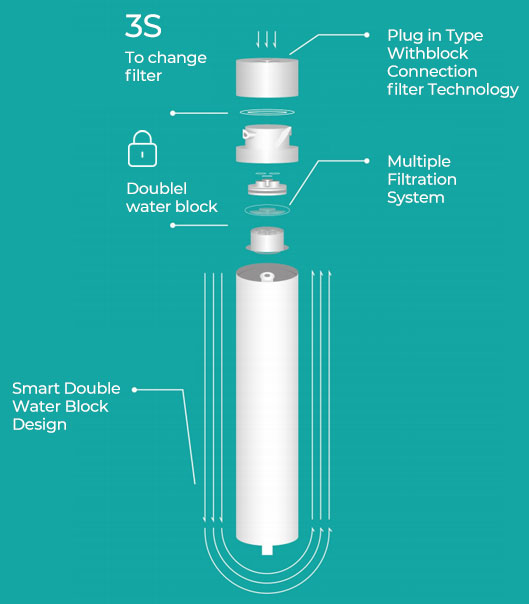

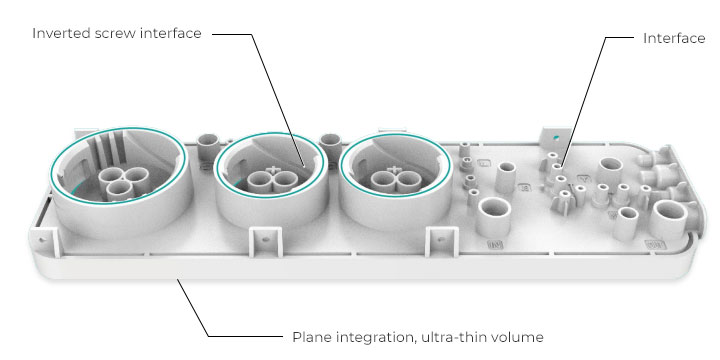

Patented structure invention, er filter element volume

Planar integration brings thinner volume and saves placement space.

Thanks to the mature application of Aibote integrated waterway technology, the internal waterway system of the product can easily realize plane integration, and the number of pipeline components and pipelines are also greatly reduced. The ultra simple internal integrated structure brings thinner volume and saves space.

Flexible customization, easy realization of various shapes, can design the main board structure for different waterway operation, and combine with rich overall product appearance, making it possible for personalized customization of water purification products.

silent

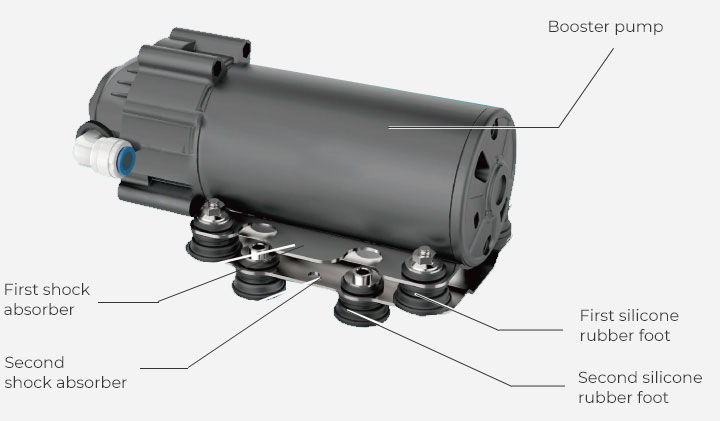

Original double shock absorption technology, double noise reduction, less noise and more mute.

Aibote double shock absorption technology can effectively reduce the noise caused by the operation of supercharging equipment and the impact of water flow. By installing double-layer damping modules on the supercharging equipment, the vibration of the supercharging equipment is weakened layer by layer, which avoids the problem of large noise caused by hard connection between the supercharging pump and the shell by using single-layer supports in traditional structures.