The intelligent control system of the Smart RO Pure Drinking Water Purification Station has an automatic flushing function, which is the key to maintaining the long-term and efficient operation of the equipment. The system's automatic flushing is set based on a preset time interval or the accumulation of treated water volume. It removes impurities, contaminants and concentrates accumulated on the RO membrane and other filter components by reverse flushing or forward flushing. This function not only extends the service life of the filter, but also ensures the continuous stability of the water quality, and reduces the risk of water quality degradation and equipment failure caused by untimely or incomplete manual flushing.

The intelligent control system can accurately monitor and record the use of each filter through built-in sensors and algorithms, including key data such as cumulative treated water volume and usage time. When the filter approaches its design life or its performance begins to decline, the system will issue a visual or audible alarm to remind the user to replace the filter in time. This function avoids the deterioration of water quality due to expired filters, and also reduces the additional costs caused by premature replacement.

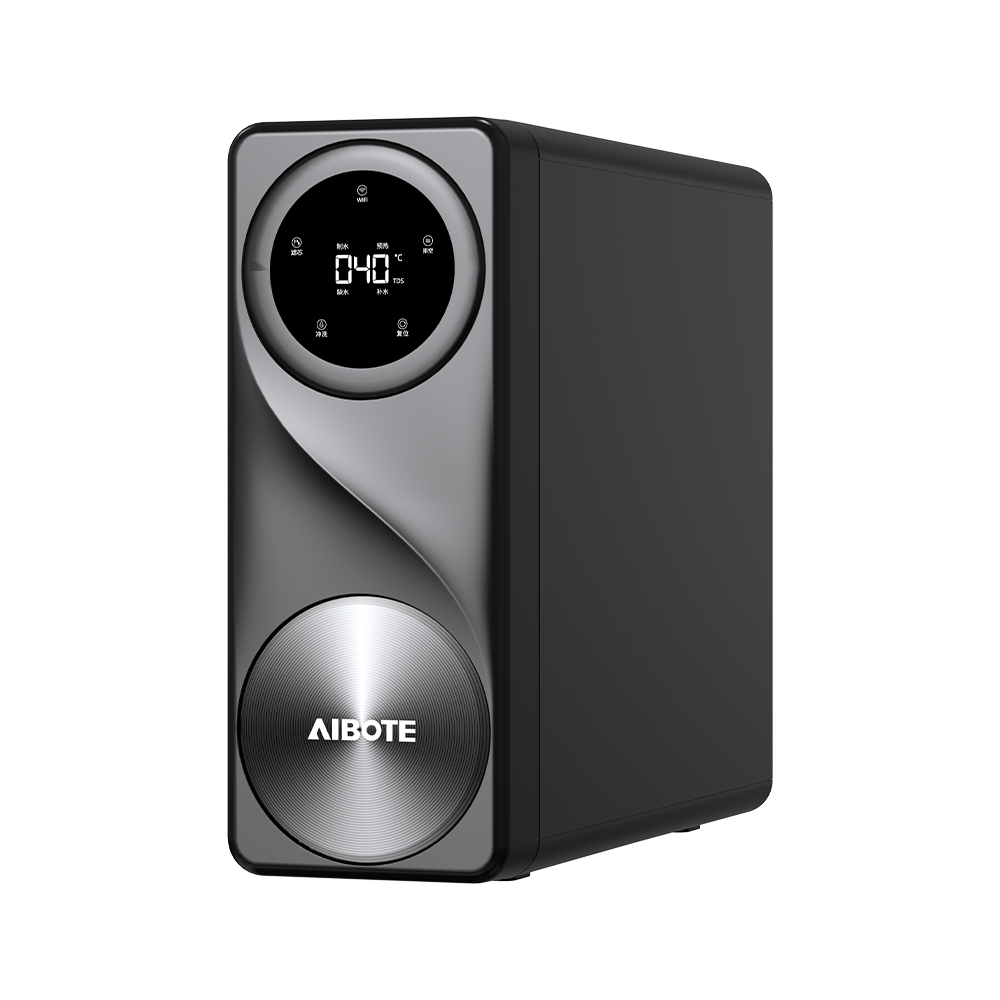

The system is equipped with an advanced fault detection mechanism that can monitor the operating status of the equipment in real time, including key parameters such as water flow, pressure, temperature, and conductivity. Once an abnormal situation is found, such as filter blockage, water pump failure, water leakage, etc., the system will immediately sound an alarm and display specific fault information on the display screen to help users quickly locate the problem. This greatly reduces the impact of equipment failure on daily drinking water supply and improves maintenance efficiency.

The intelligent control system can monitor water quality parameters and equipment status in real time, including conductivity, temperature, pressure, flow, etc., and record these data. Users can view historical data through the system interface to track and analyze water quality changes and optimize equipment use and maintenance strategies. This data-driven decision support makes equipment management and maintenance more scientific and efficient.

According to the real-time monitored water quality parameters and equipment status, the intelligent control system can automatically adjust the working status of each treatment link, such as adjusting the recovery rate of the RO membrane, the speed of the water pump, etc., to ensure the stability of the effluent quality. In addition, the system can automatically optimize the operating parameters of the equipment based on historical data and user preferences to improve the energy efficiency and effluent quality of the equipment.

Some Smart RO Pure Drinking Water Purification Stations support remote control and management functions. Users can remotely monitor equipment status, adjust operating parameters, view historical data, etc. through mobile phone APP or computer. This remote management method allows users to understand the status of the equipment anytime and anywhere, respond to equipment failures or maintenance needs in a timely manner, and improve the flexibility and efficiency of equipment management.

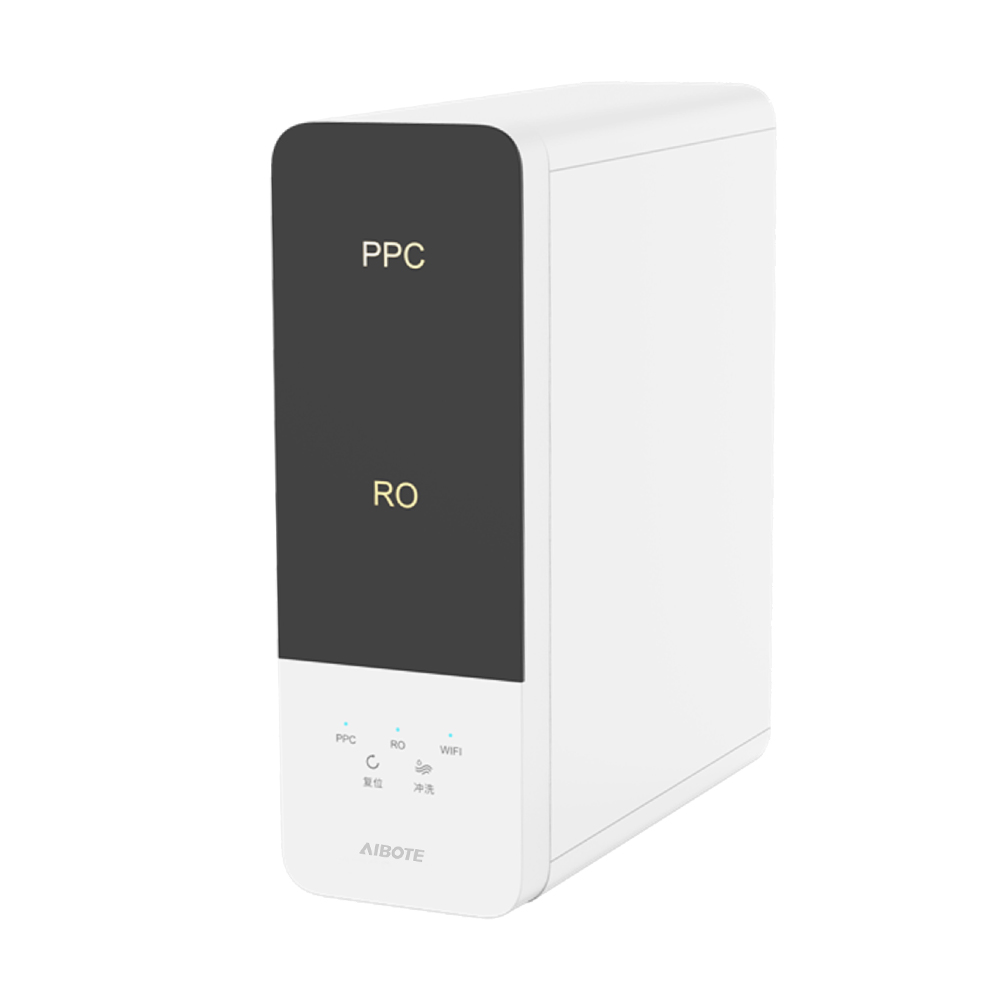

Intelligent control systems are usually equipped with a touch screen human-computer interaction interface, which is simple and intuitive and easy to operate. Users can understand the status of the equipment, set operating parameters, view alarm information, etc. through the interface. In addition, the interface also supports multi-language switching to adapt to the usage habits of users in different countries and regions. This humanized design allows users to get started easily and reduces the difficulty of operation.

The intelligent control system has built-in multiple safety protection mechanisms, such as overvoltage protection, overcurrent protection, and water leakage alarm. These protection mechanisms can cut off the power supply or sound an alarm in time when the equipment is abnormal, preventing equipment damage or personal injury accidents. At the same time, for operation steps involving personal safety, the system also sets up strict permission verification procedures, such as password protection and fingerprint recognition, to ensure that only authorized personnel can operate.

English

English

Español

Español

عربى

عربى